Polyvalve Poly-Gas® valves are everything you'd expect from the company that invented polyethylene valves.

Millions of Polyvalve Poly-Chem® valves have been sold since 1976 and are in use throughout the world. Here's why:

| Resin Supplier | Material Description | Color | ASTM Material Designation | Material Density |

|---|---|---|---|---|

| Dow | DGDA 2490 | Black | PE 4710/3408 | High |

| Temperature | SDR 9 | SDR 11 | SDR 13.5 | SDR 15.5 | SDR 17 |

|---|---|---|---|---|---|

| psig | psig | psig | psig | psig | |

| bar | bar | bar | bar | bar | |

| Acids, bases, dry gas gathering, drain water, and salt water | |||||

| 74°F | 200 | 160 | 128 | 110 | 100 |

| 23°C | 13.8 | 11 | 8.8 | 7.6 | 6.9 |

| 140°F | 100 | 80 | 64 | 55 | 50 |

| 60°C | 6.9 | 5.5 | 4.4 | 3.8 | 3.4 |

| Gaseous Hydrocarbons | |||||

| 74°F | 128 | 102 | 82 | 71 | 64 |

| 23°C | 8.8 | 7.1 | 5.3 | 4.9 | 4.4 |

| 140°F | 64 | 51 | 41 | 35 | 32 |

| 60°C | 4.4 | 3.5 | 2.8 | 2.4 | 2.2 |

| Liquid Hydrocarbons | |||||

| 74°F | 100 | 80 | 64 | 55 | 50 |

| 23°C | 6.9 | 5.5 | 4.4 | 3.8 | 3.4 |

| 140°F | 50 | 40 | 32 | 28 | 25 |

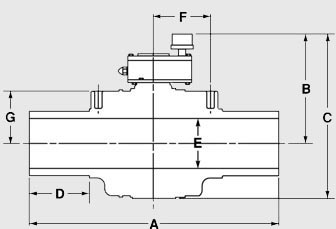

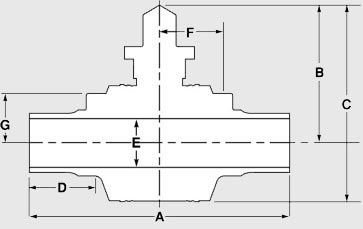

| Size | Port | A | B | C | D | E | Weight (lbs.) |

|---|---|---|---|---|---|---|---|

| 1/2 | full | 10.0 | 3.4 | 4.8 | 2.8 | 0.50 | 1.2 |

| 3/4 | full | 10.0 | 3.4 | 4.8 | 2.8 | 0.75 | 1.2 |

| 1 | standard | 10.0 | 3.4 | 4.8 | 2.8 | 0.90 | 1.2 |

| 1-1/4 | standard | 10.0 | 3.4 | 4.8 | 2.8 | 0.90 | 1.2 |

| 2 | full | 14.7 | 6.4 | 9.1 | 4.2 | 1.82 | 3.8 |

| 3 | full | 15.0 | 8.0 | 11.4 | 3.5 | 2.50 | 8.9 |

| standard | 12.8 | 6.4 | 9.1 | 3.6 | 1.95 | 4.5 | |

| 4 | full | 20.0 | 10.4 | 15.0 | 3.1 | 3.62 | 19.5 |

| standard | 15.0 | 8.0 | 11.4 | 3.8 | 2.50 | 8.9 | |

| 6 | full | 21.0 | 12.6 | 18.6 | 3.9 | 5.20 | 38.0 |

| standard | 20.0 | 10.4 | 15.0 | 5.3 | 3.62 | 23.0 | |

| 8 | full | 69.8 | 12.5 | 19.9 | 24.0 | 6.30 | 98.0 |

| Gear Operated | |||||||

| 8 | full | 69.8 | 14.8 | 22.2 | 24.0 | 6.30 | 134.0 |

| 12 | full | 83.8 | 17.5 | 27.7 | 30.0 | 9.91 | 305.0 |

| Size | Port | A | B | C | D | E | Weight (lbs.) |

|---|---|---|---|---|---|---|---|

| 16-20 | full | 254 | 86 | 122 | 71 | 12.7 | 0.5 |

| 25 | full | 254 | 86 | 122 | 71 | 19.1 | 0.5 |

| 32 | standard | 254 | 86 | 122 | 71 | 22.9 | 0.5 |

| 40 | standard | 254 | 86 | 122 | 71 | 22.9 | 0.5 |

| 55-63 | full | 373 | 164 | 231 | 106 | 46.2 | 1.7 |

| 90 | full | 381 | 203 | 290 | 89 | 63.5 | 4.0 |

| standard | 325 | 164 | 231 | 91 | 48.0 | 2.0 | |

| 100-110 | full | 508 | 264 | 381 | 77 | 91.9 | 8.8 |

| standard | 381 | 203 | 290 | 95 | 63.5 | 4.0 | |

| 150-160 & 180 | full | 533 | 320 | 472 | 99 | 132.1 | 17.2 |

| 125-160 | standard | 508 | 263 | 381 | 133 | 91.9 | 10.4 |

| 225 | full | 1773 | 318 | 504 | 610 | 160.0 | 44.5 |

| Gear Operated | |||||||

| 225 | full | 1773 | 376 | 564 | 610 | 160.0 | 60.8 |

| 315 | full | 2129 | 443 | 704 | 762 | 251.7 | 138.3 |

Note: Polyvalve proudly offers pup lengths to customer specifications.

| Item | Cat A Trim | Cat B Trim | Cat C Trim | Cat D Trim |

|---|---|---|---|---|

| Body | HDPE | HDPE | HDPE | Special Applications |

| Ball | Polypropylene | Polypropylene | Polypropylene | |

| Seat Retainers | Polypropylene | Polypropylene | Polypropylene | |

| Seats | EPDM | EPDM | Viton A | |

| Stem | Modified Polyethylene Oxide | Poly-etherimide | Poly-etherimide | |

| Stem Seals | EPDM | EPDM | Viton A | |

| Groundwater Seal | Buna | Buna N | Buna N | |

| Wrench Adapter | Polypropylene | Polypropylene | Polypropylene | |

| Primary Applications 2″ full port through 12″ full port | Strong bases: Hydroxides, caustics Organic acids: Acetic Ammonia and ammonium salt solutions Nonpotable water Air and inert gases | Alcohols and glycols |

Metal salt solutions: Bicarbonates, bromides, carbonates, chlorides, cyanides, ferri-cyanides, fluorides, hypochlorites, nitrates, oxides, phosphates, sulphates, or sulphides, of Aluminum, Barium, Calcium, Copper, Iron, Magnesium, Mercury, Nickel, Potassium, Silver, Sodium, Tin, or Zinc.

Other: Crude oil, produced water, carbon dioxide, hydrogen sulphide, landfill methane and leachate, hydrogen peroxide. |

For inorganic acids such as hydrochloric, nitric, sulphuric, phosphoric, hydrofluoric and boric please contact Polyvalve for valve recommendations.

| Size | Body Pieces | Port | End Configuration | Cv | Kv | Equiv. Length of Pipe (ft.) | Available SDRs | |

|---|---|---|---|---|---|---|---|---|

| In. | metric | |||||||

| 2 | 55-63 | 3 | full | BF | 175 | 2528 | 3.8 | 9.3, 11 |

| 3 | 90 | 3 | full | BF | 390 | 5624 | 5.3 | 9.3, 11, 13.5 |

| 3 | standard | BF | 240 | 3461 | 14.1 | 9.3, 11, 13.5 | ||

| 4 | 100-110 | 3 | full | BF | 700 | 10094 | 5.8 | 9.3, 11, 13.5 |

| 3 | standard | BF | 400 | 5768 | 17.8 | 9.3, 11, 13.5 | ||

| 6 | 150-160- 180 | 3 | full | BF | 1800 | 25957 | 6.1 | 9.3, 11, 13.5 |

| 3 | standard | BF | 900 | 12978 | 24.3 | 9.3, 11, 13.5 | ||

| 8 | 225 | 2 | full | BF | 3650 | 52633 | 5.5 | 11, 13.5 |

| 12 | 315 | 3 | full | BF | 7000 | 73542 | 10.6 | 11, 13.5 |

Note: Cv in US gal/min @ 1 psi ΔP. Kv in US gal/min @ 1 psi ΔP

2"-12" Design